Correct Answer

verified

Correct Answer

verified

Multiple Choice

In which type of operation are you likely to see, at most, only minor variations in the product or service being produced using the same process and the same equipment?

A) a project

B) a job shop

C) repetitive production

D) batch processing

E) intermittent production

Correct Answer

verified

Correct Answer

verified

Multiple Choice

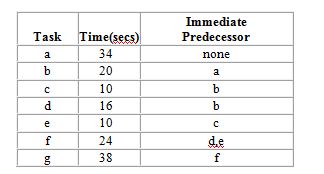

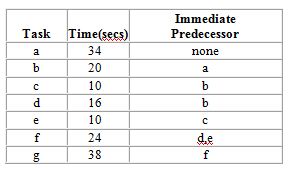

QRS Corp. is designing a product layout for a new product. They plan to use this production line 10 hours a day in order to meet forecasted demand of 900 units per day. The following table describes the tasks necessary to produce this product:  For output to equal forecasted demand, what will be the efficiency of the production line that uses the least number of workstations?

For output to equal forecasted demand, what will be the efficiency of the production line that uses the least number of workstations?

A) 81 percent

B) 90 percent

C) 95 percent

D) 85 percent

E) 100 percent

Correct Answer

verified

Correct Answer

verified

Multiple Choice

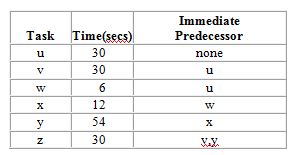

A company is designing a product layout for a new product. It plans to use this production line eight hours a day in order to meet projected demand of 480 units per day. The tasks necessary to produce this product are:  If the company wants the output rate to be equal to demand, what is the theoretical minimum number of workstations needed?

If the company wants the output rate to be equal to demand, what is the theoretical minimum number of workstations needed?

A) 3

B) 4

C) 5

D) 6

E) 7

Correct Answer

verified

Correct Answer

verified

Multiple Choice

Which phrase most closely describes flexible manufacturing systems?

A) a variation of CAD

B) a more fully automated version of cellular manufacturing

C) manufacturing resource planning

D) a process layout with a manufacturing overlay

E) an approach that allows workers to begin work at a time of their choosing

Correct Answer

verified

Correct Answer

verified

True/False

A job-shop processing system generally requires less-skilled workers than a continuous processing system.

Correct Answer

verified

Correct Answer

verified

True/False

There are three basic process types: input, processing, and output.

Correct Answer

verified

Correct Answer

verified

Multiple Choice

The advantages of automation include: (I) reduced output variability. (II) reduced variable costs. (III) machines don't strike or file grievances. (IV) machines are always less expensive than human labor.

A) I and IV

B) II and III

C) I, II, and III

D) I and III

E) II and IV

Correct Answer

verified

Correct Answer

verified

True/False

Repetitive processing systems repetitively rotate production through small batches of a variety of products.

Correct Answer

verified

Correct Answer

verified

Multiple Choice

In which type of processing system would gasoline be produced from crude oil?

A) job shop

B) batch

C) assembly

D) continuous

E) project

Correct Answer

verified

Correct Answer

verified

True/False

Information technology refers to competitive data.

Correct Answer

verified

Correct Answer

verified

Multiple Choice

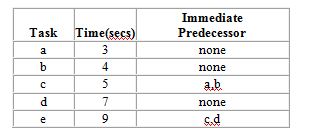

A company needs to rebalance a product layout for producing new plastic license plates. They plan to use the assembly line six hours in order to meet projected demand of 2,160 license plates each day. The following table describes the tasks involved in the production of this product:  For output to equal projected demand, what will be the efficiency of the assembly line that uses the minimum number of workstations?

For output to equal projected demand, what will be the efficiency of the assembly line that uses the minimum number of workstations?

A) 0.0 percent

B) 6.7 percent

C) 70.0 percent

D) 93.3 percent

E) 100 percent

Correct Answer

verified

Correct Answer

verified

Multiple Choice

Which of the following is not a characteristic of layout decisions in system design?

A) substantial investment of both money and effort

B) long-term commitment

C) significant impact on short-term efficiency

D) usually well received by operative personnel

E) can affect supplier or customer processes

Correct Answer

verified

Correct Answer

verified

True/False

The term "computer-aided manufacturing" refers primarily to the use of robotics in process control.

Correct Answer

verified

Correct Answer

verified

Multiple Choice

QRS Corp. is designing a product layout for a new product. They plan to use this production line 10 hours a day in order to meet forecasted demand of 900 units per day. The following table describes the tasks necessary to produce this product:  For output to equal forecasted demand, what is the theoretical minimum number of workstations needed?

For output to equal forecasted demand, what is the theoretical minimum number of workstations needed?

A) 1

B) 3

C) 3.75

D) 4

E) 5

Correct Answer

verified

Correct Answer

verified

Multiple Choice

Which one of the following is not considered an important factor in retail layout design?

A) cost minimization

B) traffic patterns and traffic flow

C) opportunity to influence customer attitudes

D) degree of contact with the customer

E) degree of customization

Correct Answer

verified

Correct Answer

verified

Multiple Choice

Computer-aided manufacturing refers to the use of computers in:

A) product design.

B) decision making.

C) data analysis.

D) quality control.

E) process control.

Correct Answer

verified

Correct Answer

verified

Multiple Choice

Key aspects of the process selection challenge include _________ and __________.

A) information technology; marketing strategy

B) process flexibility; marketing strategy

C) capital intensity; process flexibility

D) marketing strategy; operations strategy

E) capacity planning; marketing strategy

Correct Answer

verified

Correct Answer

verified

Multiple Choice

The maximum allowable cycle time is computed as:

A) daily operating time divided by the desired output.

B) desired output divided by the daily operating time.

C) daily operating time divided by the product of the desired output and the sum of job times.

D) the product of desired output and the sum of job times divided by daily operating time.

E) 1.00 minus station time.

Correct Answer

verified

Correct Answer

verified

Multiple Choice

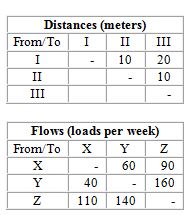

A company needs to locate three departments (X, Y, and Z) in the three areas (I, II, and III) of a new facility. They want to minimize interdepartmental transportation costs, which are expected to be $.50 per load per meter moved. An analyst has prepared the following distances and flow matrices:  What is the distance (in meters) from area III to area I in this new facility?

What is the distance (in meters) from area III to area I in this new facility?

A) 0

B) 10

C) 20

D) 30

E) 40

Correct Answer

verified

Correct Answer

verified

Showing 101 - 120 of 132

Related Exams